Top tips to optimize custom cigarette box structural strength

- Top Tips to Optimize Custom Cigarette Box Structural Strength

- 1. Choose the Right Materials for Durability

- 2. Implement Robust Structural Designs

- 3. Optimize Box Dimensions and Fit

- 4. Utilize Reinforced Packaging Techniques

- 5. Ensure Quality Printing and Coating

- 6. Conduct Rigorous Quality Control and Testing

- 7. Collaborate with Experienced Packaging Manufacturers

- 8. Stay Updated with Industry Standards and Regulations

- 9. Consider Environmental Impact and Sustainability

- 10. Invest in Professional Design and Prototyping Services

- Conclusion

- Frequently Asked Questions (FAQ)

Top Tips to Optimize Custom Cigarette Box Structural Strength

Ensuring the structural strength of your custom cigarette boxes is crucial for product safety, brand image, and consumer satisfaction. A well-designed and sturdy box not only protects the contents but also enhances the overall appeal of Best Pack. In this article, we'll explore key strategies to optimize the structural integrity of your custom cigarette packaging.

1. Choose the Right Materials for Durability

Selecting high-quality materials is the foundation of a strong cigarette box. Materials such as eco-friendly Kraft paper, E-flute corrugated board, and Bux board offer excellent durability and protection. For instance, Best Pack provides custom packaging solutions using materials like Kraft paper and E-flute corrugated board, ensuring both strength and environmental responsibility. ((https://www.gzbestpack.com/?utm_source=openai))

2. Implement Robust Structural Designs

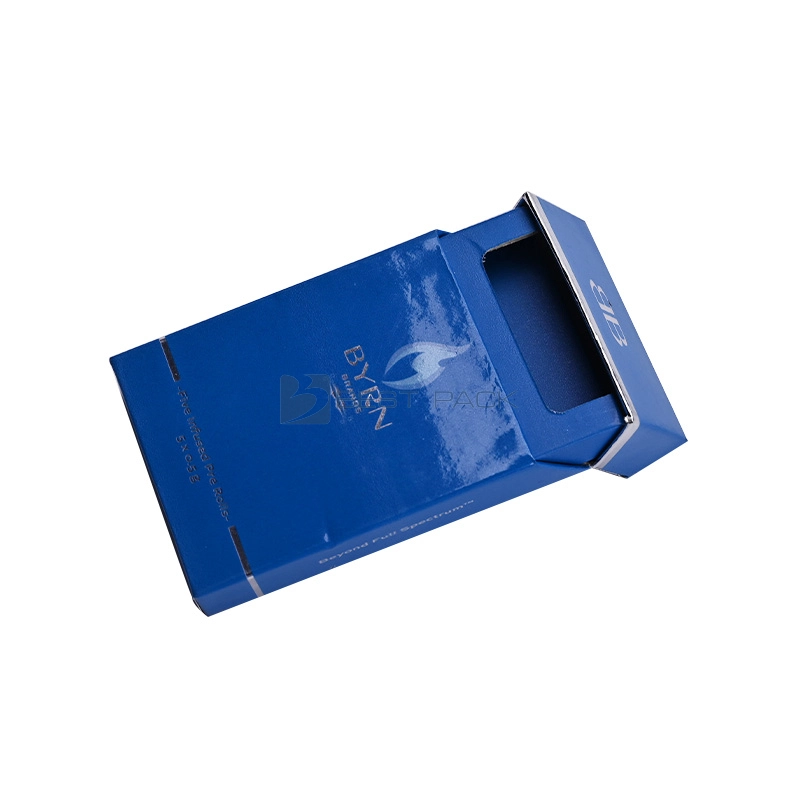

The design of your cigarette box plays a significant role in its strength. Incorporating features like auto-lock bottoms, which provide additional support without the need for glue or tape, can enhance stability. Additionally, two-piece rigid boxes offer superior protection and a premium feel. Companies like Ryt Packaging offer various structural formats, including flip-top boxes and drawer-style boxes, tailored to your product's needs.

3. Optimize Box Dimensions and Fit

Ensuring that your cigarette box dimensions are tailored to fit the product snugly prevents movement that could lead to damage. Custom sizes and styles, as offered by Custom Cigarette Boxes, allow for a perfect fit, reducing the risk of structural compromise.

4. Utilize Reinforced Packaging Techniques

Incorporating reinforcement techniques such as embossing, debossing, and foil stamping can not only enhance the aesthetic appeal but also add to the box's structural strength. These techniques can be applied to both the exterior and interior of the box to provide additional support. For example, Silver Edge Packaging offers custom colorful cigarette boxes with various customization options, including embossing and debossing.

5. Ensure Quality Printing and Coating

High-quality printing and coating not only improve the visual appeal of your cigarette box but also contribute to its durability. Using UV coating or spot UV can protect the box from scratches and wear, maintaining its structural integrity over time. Companies like Liquid Printer provide custom printed cigarette boxes with various coating options to enhance durability.

6. Conduct Rigorous Quality Control and Testing

Before mass production, it's essential to conduct thorough quality control and testing to ensure that the boxes meet structural strength standards. This includes testing for compression resistance, impact resistance, and overall durability. Best Pack emphasizes quality control in their manufacturing process to ensure the highest standards are met. ((https://www.gzbestpack.com/?utm_source=openai))

7. Collaborate with Experienced Packaging Manufacturers

Partnering with experienced packaging manufacturers can provide valuable insights and expertise in optimizing box structural strength. Companies like Best Pack offer one-stop custom packaging solutions, combining innovative design, top-quality production, and competitive pricing. ((https://www.gzbestpack.com/?utm_source=openai))

8. Stay Updated with Industry Standards and Regulations

Adhering to industry standards and regulations ensures that your cigarette boxes are not only structurally sound but also compliant with legal requirements. Staying informed about packaging regulations can prevent costly redesigns and ensure market acceptance.

9. Consider Environmental Impact and Sustainability

Opting for sustainable materials and practices not only appeals to environmentally conscious consumers but also contributes to the overall strength and quality of the packaging. Companies like The Speedy Pack offer premium cardboard cigarette boxes made from durable, eco-friendly materials, ensuring both strength and environmental responsibility.

10. Invest in Professional Design and Prototyping Services

Investing in professional design and prototyping services can help identify potential structural weaknesses before mass production. This proactive approach allows for adjustments and improvements, ensuring the final product meets all strength and durability criteria.

Conclusion

Optimizing the structural strength of your custom cigarette boxes is essential for product protection, brand image, and consumer satisfaction. By selecting the right materials, implementing robust designs, and collaborating with experienced manufacturers, you can create packaging that not only safeguards your product but also enhances its market appeal.

Frequently Asked Questions (FAQ)

Q1: What materials are best for ensuring the structural strength of cigarette boxes?

A1: Materials such as eco-friendly Kraft paper, E-flute corrugated board, and Bux board are excellent choices for durable cigarette boxes. These materials offer both strength and environmental benefits.

Q2: How can design features enhance the structural integrity of cigarette boxes?

A2: Incorporating design features like auto-lock bottoms, two-piece rigid boxes, and reinforcement techniques such as embossing and debossing can significantly enhance the structural strength of cigarette boxes.

Q3: Why is quality control important in the manufacturing of cigarette boxes?

A3: Rigorous quality control ensures that the boxes meet structural strength standards, preventing potential product damage and maintaining brand reputation.

Q4: How can sustainable practices impact the strength of cigarette boxes?

A4: Sustainable materials and practices can contribute to the overall strength and quality of the packaging, appealing to environmentally conscious consumers and enhancing brand image.

Q5: What role does professional design and prototyping play in optimizing box strength?

A5: Professional design and prototyping services help identify potential structural weaknesses before mass production, allowing for necessary adjustments to ensure the final product meets all strength and durability criteria.

For more information or to discuss your custom cigarette packaging needs, please contact us or explore our product offerings.

How to create child-resistant prototypes for cigarette boxes

How to reduce tampering with a custom cigarette box

Top Logo Printing Techniques for Cigarette Packaging

Best Printing Techniques for Pre-Roll Packaging Boxes

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

How do you ensure product quality?

We maintain strict quality control at every stage, from material selection to final production, ensuring high-quality standards.

About us

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack