Why RGB Is Not Used for Printing?

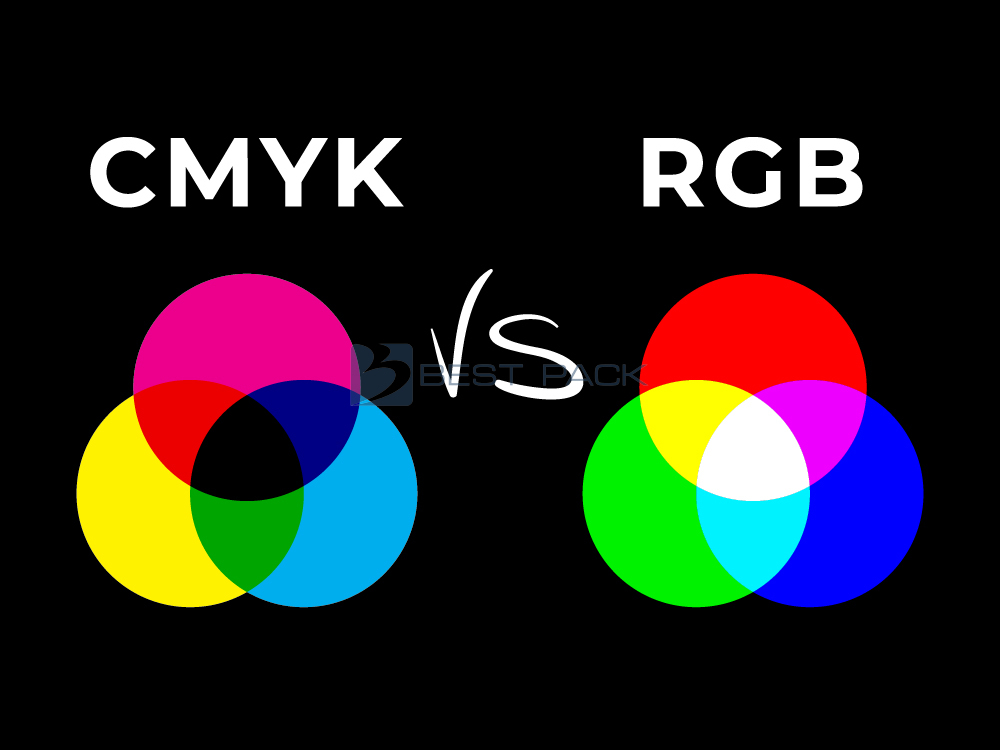

In the world of design and visual media, two major color systems are commonly used: RGB and CMYK. While RGB (Red, Green, Blue) is used for digital displays, it is not suitable for printing. Instead, printers use the CMYK (Cyan, Magenta, Yellow, Black) color model. But why is that?

✅ What Is RGB?

RGB is a light-based color model used for screens—such as monitors, smartphones, TVs, and digital cameras. Colors are created by combining red, green, and blue light at different intensities. The more light you add, the brighter the color becomes.

-

RGB is additive:

Red + Green + Blue = White light

No light = Black

✅ Why RGB Doesn’t Work for Printing

-

1.Printing Uses Ink, Not Light

Printing is a physical process that applies ink or toner to paper. Unlike screens that emit light, printed materials reflect light. This requires a different method of color creation—hence the use of CMYK, which is a subtractive model (the more ink you add, the darker it gets). -

2.RGB Has a Wider Gamut Than CMYK

RGB can display more vibrant and luminous colors than CMYK, especially neons and bright blues/greens. However, printers cannot 3.reproduce all RGB colors, so files designed in RGB may look dull or inaccurate when printed. -

Color Accuracy and Control

Printers are calibrated to interpret CMYK values. If you send a design in RGB, the software or printer must automatically convert it, often resulting in unexpected color shifts. -

4.Professional Print Standards

For packaging, brochures, catalogs, and branded materials, professional printers require CMYK or Pantone (spot color) files to ensure predictable and consistent output.

✅ Conclusion

RGB is for screens; CMYK is for print.

Designing in RGB for print can lead to inaccurate, faded, or incorrect colors on the final product. To ensure color consistency and professional results, always convert or design your files in CMYK mode before printing.

About us

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Get in Touch with Best Pack

We’re here to help bring your ideas to life!

Best pack

Best pack

Best pack