How to select a factory for customized pre roll printing

- How to Select a Factory for Customized Pre Roll Printing

- Why the right factory matters for pre roll packaging

- Understand your product and packaging requirements

- Verify relevant certifications and compliance

- Assess print quality and color management for pre roll packaging

- Inspect factory capabilities: tooling, MOQ, and lead times

- Quality control systems and inspection processes

- Production cost breakdown and negotiation points

- Supply chain resilience and material sourcing

- Child-resistant and safety considerations for pre roll packaging

- Comparison table: Key factory selection criteria

- Sampling, proofs, and pilot runs

- Logistics, shipping, and after-sales support

- Red flags to watch for when vetting a factory

- Case example: Applying these steps to Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

- Brand advantages when partnering with a specialized factory

- Final checklist before signing a contract

- FAQ — Frequently Asked Questions

- Q: What is the typical minimum order quantity (MOQ) for custom pre roll packaging?

- Q: How long does it take to get samples and a full production run?

- Q: Can factories provide child-resistant features for paperboard pre roll boxes?

- Q: What sustainable options exist for pre roll packaging?

- Q: How do I ensure color consistency across multiple production runs?

- Contact us / See the product

- References and sources

How to Select a Factory for Customized Pre Roll Printing

Why the right factory matters for pre roll packaging

Selecting the right manufacturer for your custom pre roll printing is more than a cost decision—it's a brand, compliance, and customer-safety decision. High-quality pre roll packaging protects fragile non-tobacco herbal pre-rolls or CBD/THC joints, conveys Best Packing, and ensures consistent shelf appeal. The wrong supplier can lead to production delays, inconsistent colors and finishes, poor material choices, and even regulatory or child-safety compliance issues. This guide walks through the essential criteria, verification steps, and negotiation points you need to securely partner with a factory that delivers consistent, on-brand pre roll packaging—specifically for products like Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes.

Understand your product and packaging requirements

Before contacting factories, document precise product specifications. For pre roll packaging this should include:

- Outer dimensions, internal structure (tray, sleeve, insert), and exact capacities (e.g., 5-pack, 10-pack, 20-pack).

- Material choices: paperboard thickness (GSM/pt), board type (SBS, GC1, FBB), and whether you need coated or uncoated surfaces.

- Printing requirements: full-color CMYK, PMS/Pantone color match, varnish, UV or matte coating, embossing/debossing, foil stamping.

- Functional requirements: child-resistant features, odor barrier, tear strips, reseal capability.

- Regulatory/labeling needs: warning panels, ingredient declarations, batch/lot codes, serialization.

Having a clear spec sheet speeds initial quotes and avoids costly misinterpretations during sampling and production.

Verify relevant certifications and compliance

Trustworthy factories will display accepted quality and environmental certifications. For pre roll packaging you should prioritize:

- ISO 9001 (Quality Management) to indicate consistent production processes.

- FSC (Forest Stewardship Council) or PEFC for sustainable paper sourcing if you market eco-friendly packaging.

- GMP or equivalent manufacturing best-practices to support cleanliness and traceability—important where packaging touches consumable herbal products.

- Local regulatory compliance relevant to your market (for example, child-resistant packaging standards in some jurisdictions or specific labeling requirements for cannabinoids).

Ask factories to provide copies of certificates and confirm they can meet any region-specific standards you must follow.

Assess print quality and color management for pre roll packaging

Color consistency is critical for brand integrity. Ask potential factories about their color-management process and the tools they use to control color across batches:

- Do they work in CMYK and support Pantone (PMS) spot colors?

- Can they provide print proofs (digital and hard-press) and DOEs (digital color proof vs. press proof) for approval?

- What presses do they use? (Flexo, offset, digital). For High Quality finishes such as foil stamping, embossing, or tactile coatings, confirm they have the equipment and skilled operators.

Always request a full-production press sample on the same stock and finish you intend to order. Approve mechanical dielines and color proofs before bulk runs.

Inspect factory capabilities: tooling, MOQ, and lead times

Packaging factories vary significantly in tooling capacity and minimum order quantities (MOQs). Important points to confirm:

- Tooling: Do they offer in-house die cutting, gluing, and finishing? Will they create and hold tooling files for repeat orders?

- MOQ: Understand the MOQ for custom pre roll packaging—some factories have fixed MOQs per SKU; others scale by design complexity.

- Lead times: Ask for sample lead time, tooling lead time, and mass-production lead time, and what affects changes (season, material availability).

Lower-cost suppliers may have lower tooling quality or higher defect rates; High Quality factories often require higher MOQs but deliver better consistency and faster re-runs.

Quality control systems and inspection processes

Reliable QC reduces returns and protects brand reputation. Verify the factory's QC regimen:

- Incoming materials inspection (board weight, surface finish).

- Inline checks during printing and finishing (registration, ink density, varnish coverage).

- Final inspection criteria (AQL levels—Acceptance Quality Limit) and sample size methodology.

- Third-party inspection allowances (pre-shipment inspection by your agent or a neutral QA firm).

Ask for samples of their QC reports and request to witness an inspection (virtually or onsite) before approving final shipments.

Production cost breakdown and negotiation points

Price is important, but lowest bid rarely wins in the long-term. Request a transparent cost breakdown that includes:

- Tooling and setup costs (die, plates, molds).

- Unit price at several quantity tiers (5k, 10k, 25k, etc.), and how price scales with order size.

- Finishing charges (foil, emboss, coatings) and special handling fees (child-resistant mechanisms, odor-barrier lamination).

- Packing, labeling, and shipping assistance (palletization, drop-shipping capabilities).

Negotiate payment terms and schedule: common terms include 30% deposit for tooling and balance on shipment, or letter of credit for larger orders.

Supply chain resilience and material sourcing

Ensure the factory can manage supply chain disruptions—this is critical for consistent pre roll packaging supply. Questions to ask:

- Do they maintain safety stock for core substrates and inks?

- Can they source alternative approved materials quickly if your specified paperboard is unavailable?

- Do they work with multiple suppliers for critical components like child-resistant closures or specialized films?

Factories with diversified sourcing and transparent material traceability protect you from sudden delays or quality downgrades.

Child-resistant and safety considerations for pre roll packaging

If your product requires child-resistant features—or you choose to use them for consumer safety—you must confirm the factory's experience with such mechanisms. Important checks:

- Has the factory produced packages that meet local child-resistance testing protocols? (Standards vary per region.)

- Can they integrate mechanical or multi-step opening features into paperboard cases while maintaining print and finish quality?

- Do they provide documentation or test reports for child-resistant performance?

In many cases you will need third-party testing; the factory should support sample submission and iterative design changes to pass testing.

Comparison table: Key factory selection criteria

| Criterion | Why it matters | Recommended threshold | Source |

|---|---|---|---|

| ISO 9001 | Process control and consistent quality | Factory certified within last 3 years | ISO (quality standards) |

| FSC/PEFC | Sustainable paper sourcing for brand trust | FSC or equivalent for primary board | FSC/PEFC guidance |

| MOQ | Cost per SKU and inventory planning | Match to forecast; request price tiers | Supplier negotiation best practice |

| Lead time | Time-to-market and restock speed | Sample: 7–21 days; Production: 2–6 weeks | Packaging industry norms |

| AQL / QC | Acceptable defect rate and inspection rigor | AQL 2.5 or lower for visual defects | Quality control standards |

Note: Table thresholds are guidelines; confirm specifics with factories and third-party QA resources.

Sampling, proofs, and pilot runs

Never skip sampling. The sampling phase validates materials, structure, print, and finishing. Recommended sampling sequence:

- Digital mockup proof (PDF die-lines and artwork). Review dielines, creases, and bleeds.

- Digital color proof to check layout and copy.

- Hard-press sample on actual stock with requested finishes (foil, varnish, die-cut, emboss).

- Pilot production (small-run) to test assembly, child-resistant function, and packaging endurance during shipping.

Revise and re-proof until you have a production-ready sample that you sign off on in writing.

Logistics, shipping, and after-sales support

Clarify logistics responsibilities and post-delivery support:

- Who coordinates international shipping, customs documents, and duties?

- How are damages handled in transit and what are warranty terms?

- Does the factory maintain spare tooling and offer quick re-runs if a batch has issues?

Factories that offer end-to-end support (including labeling, secondary packaging, and kitting) reduce your operational complexity.

Red flags to watch for when vetting a factory

Be wary if a supplier:

- Refuses to provide references, certificates, or sample work on the requested stock and finish.

- Has inconsistent or evasive answers about quality control and rejects rates.

- Offers prices dramatically lower than all other quotes without clear explanation (could indicate shortcuts or old/low-quality materials).

- Delays in producing press samples or refuses third-party inspections.

Trust but verify—insist on contractual terms that protect you if the factory fails to meet agreed specifications or timelines.

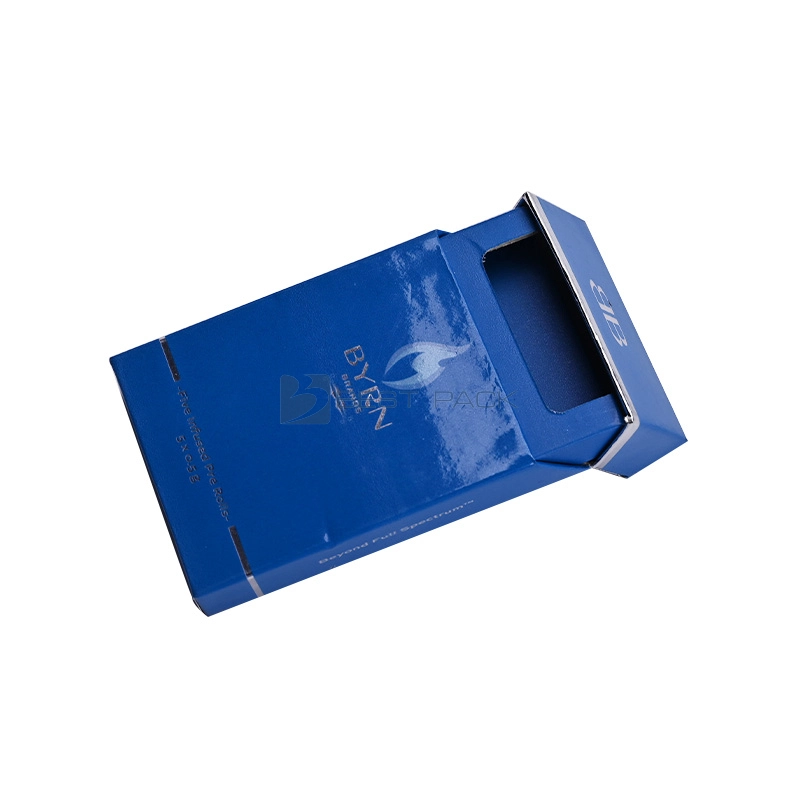

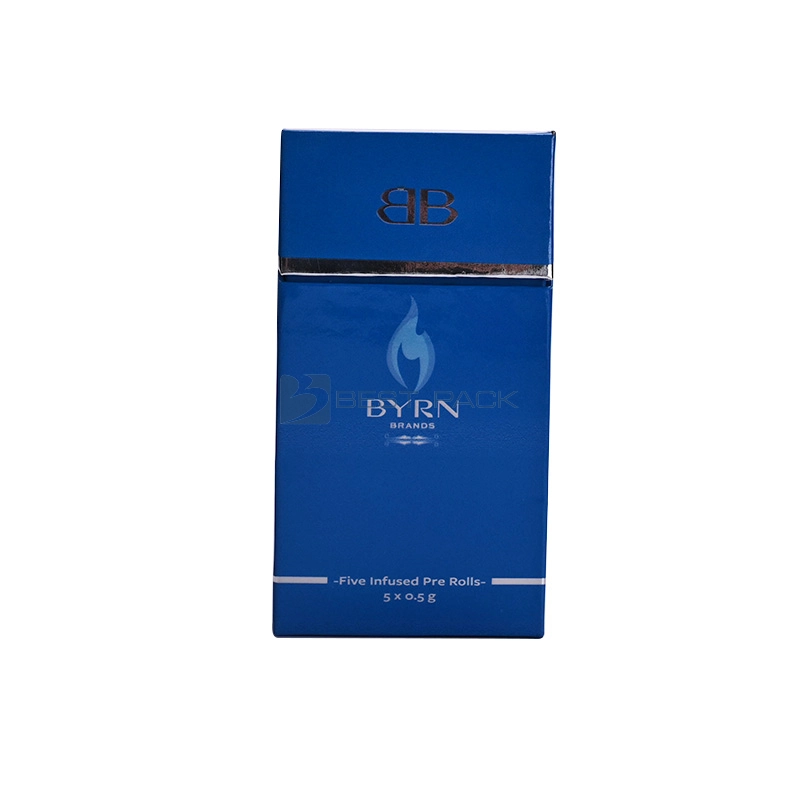

Case example: Applying these steps to Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

For a product like Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, use the above checklist as follows:

- Provide clear spec: indicate that boxes are thick paperboard, available as 5/10/20 pack configurations, require logo printing, and used for non-tobacco herbal pre-rolls.

- Request hard-press samples on the exact board thickness and finish (e.g., 16-24 pt SBS with matte aqueous coating) and confirm the factory can maintain structural integrity for multiple jostles in transit.

- Confirm child-resistant or resealable options if you plan to sell in markets that require or prefer them.

- Ask about odor-barrier lamination if the product is CBD/THC joints, and confirm regulatory labeling capabilities for your jurisdiction.

Brand advantages when partnering with a specialized factory

Working with an experienced pre roll packaging supplier delivers several brand-level benefits:

- Consistent High Quality finish that aligns with customer expectations—important for High Quality herbal products.

- Faster time-to-market via streamlined tooling and repeat-order processes.

- Integrated compliance support for labeling and child-resistant mechanisms, reducing legal risk.

- Opportunity to choose sustainable materials (FSC-certified board) that resonate with eco-conscious consumers.

- Factory-direct pricing and shorter supply chain for better margins—an advantage of products like Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes, which are positioned as factory-direct custom packaging designed for High Quality presentation and protection.

Final checklist before signing a contract

Use this checklist to finalize supplier selection:

- Obtain and verify certifications (ISO, FSC, GMP where relevant).

- Approve final dielines and press proofs in writing.

- Agree on QC standards and AQL acceptance levels.

- Confirm tooling ownership and re-run pricing.

- Set clear payment terms and penalties for late delivery or off-spec production.

FAQ — Frequently Asked Questions

Q: What is the typical minimum order quantity (MOQ) for custom pre roll packaging?

A: MOQ varies by factory and complexity. For standard die-cut paperboard boxes, MOQs can range from a few thousand to tens of thousands per SKU. If you require High Quality finishes or unique dies, the MOQ and tooling costs may be higher. Request tiered pricing to understand cost per unit at different volumes.

Q: How long does it take to get samples and a full production run?

A: Typical timelines: digital proofs within 1–3 days, hard-press samples in 7–21 days depending on tooling, and mass production 2–6 weeks after sample approval. Timelines change based on seasonal demand and material availability.

Q: Can factories provide child-resistant features for paperboard pre roll boxes?

A: Yes. Some factories can integrate mechanical or multi-step opening features into paperboard designs, or add supplemental child-resistant inserts. Confirm their experience and request test documentation or third-party test support.

Q: What sustainable options exist for pre roll packaging?

A: Choose FSC- or PEFC-certified paperboard, water-based inks, and recyclable coatings. Avoid plastic laminates if recyclability is a priority. Confirm the factory's sustainability certifications and supply-chain transparency.

Q: How do I ensure color consistency across multiple production runs?

A: Use Pantone spot colors for brand-critical elements, request ink recipes, and keep tooling & color standards on file with the factory. Periodic press checks and having a trusted QC process reduce variation.

Contact us / See the product

If you are ready to produce factory-direct custom pre-roll boxes—such as our Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes—we can help. Our factory-direct custom pre-roll and cigarette paper boxes are designed for High Quality presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Contact our sales team to request a spec sheet, production timeline, and sample quote. We offer full prepress support, press proofs, and pilot runs to ensure your pre roll packaging meets Best Pack and regulatory needs.

References and sources

- ISO — Quality management systems (ISO 9001) and standards for production quality.

- FSC / PEFC — Certification programs for responsible forest stewardship and sustainable paper sourcing.

- FDA — Guidance on packaging and food-contact materials; used for understanding safety and material considerations.

- WHO — Good Manufacturing Practices (GMP) guidance for production hygiene and traceability where applicable.

- Packaging industry publications (Packaging World, Packaging Europe, PMMI) — best practices in supplier selection, color management, and finishing processes.

Top 5 cigarette paper box Company List and Products Compared

The latest trends for cigarette pack designs

The latest trends for personalized cigarette boxes

Cigarette box style packaging for modern pre rolls

About us

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

What is the box size and structure?

1. All boxes are customized and all detailed requirements can be provided by clients, we are definitely your OEM service supplier.

2. If you have no idea about the measurements and structure on your products, our professional design team can suggest and solute for you .

FAQs

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Factory Customized Printing LOGO Pack 10 20 5 Thick Case Pre Roll Non Tobacco Paper Box Cigarette Boxes

Our factory-direct custom pre-roll and cigarette paper boxes are designed for premium presentation, protection, and branding. Made with thick, durable paperboard, these boxes are ideal for non-tobacco herbal pre-rolls, cigarettes, or CBD/THC joints. Available in various capacities (5-pack, 10-pack, 20-pack) and fully customizable with your logo and design.

Custom Luxury Pre Roll Packaging Boxes with Child-Resistant Paper Tray

Our luxury pre-roll packaging boxes are designed to combine elegant presentation with top-tier safety features. Featuring a child-resistant mechanism and a custom paper tray insert, these boxes ensure secure storage while delivering a premium unboxing experience for pre-roll products.

Best pack

Best pack

Best pack