What Is a Child-Resistant Pre-Roll Packaging Box?

- What Is a Child-Resistant Pre-Roll Packaging Box?

- Definition: pre roll packaging box explained

- Why brands need a child-resistant pre roll packaging box

- Regulations and standards that affect pre roll packaging box requirements

- Key regulatory drivers for child-resistant packaging

- Design features of an effective child-resistant pre roll packaging box

- Mechanical and structural elements to look for

- Materials and sustainability considerations for pre roll packaging box

- Material choices: paperboard, plastic, metal and alternatives

- Testing and certification for child-resistant pre roll packaging box

- How compliance is proven

- Comparing popular child-resistant pre roll packaging box types

- Which design fits your product and brand?

- How to choose the right pre roll packaging box for Best Pack

- Decision factors: compliance, cost, brand experience

- Manufacturing and customization: bringing a pre roll packaging box to market

- Working with a packaging partner

- Best Pack: custom solutions for child-resistant pre roll packaging box

- Who we are and what we offer

- Our product range and core competencies

- Our vision and customer value

- Cost considerations and lead times for your pre roll packaging box

- Budgeting and production planning

- Real-world best practices for packaging safety and marketing

- Balancing safety with brand impact

- Frequently Asked Questions (FAQ)

- Do all states require a child-resistant pre roll packaging box?

- Does 'child-resistant' mean 'child-proof'?

- How is a pre roll packaging box tested for child-resistance?

- Can child-resistant features be combined with sustainable materials?

- How long does it take to develop a custom child-resistant pre roll packaging box?

- Why choose Best Pack for custom pre roll packaging box solutions?

- Contact us / View our products

- Ready to design your child-resistant pre roll packaging box?

- References

What Is a Child-Resistant Pre-Roll Packaging Box?

Definition: pre roll packaging box explained

A child-resistant pre roll packaging box is a specially designed container for pre-rolled cannabis cigarettes (pre-rolls) that reduces the likelihood children can open and access the product. While maintaining shelf appeal and brand messaging, these boxes incorporate mechanical or engineering features — such as push-and-turn locks, two-step opening sequences, or tamper-evident seals — to meet safety requirements and protect young children from accidental ingestion. For brands selling cannabis products, investing in a certified child-resistant pre roll packaging box is both a legal obligation in many jurisdictions and a responsible safety practice.

Why brands need a child-resistant pre roll packaging box

Child safety, regulatory compliance, and consumer trust are the top reasons brands choose child-resistant pre roll packaging box solutions. Children are naturally curious, and cannabis products often resemble everyday items. A properly designed pre roll packaging box minimizes accidental exposures and aligns your product with local and national rules for controlled substances and tobacco-like products. Using a certified solution also reduces liability and supports brand reputation as safety-first.

Regulations and standards that affect pre roll packaging box requirements

Key regulatory drivers for child-resistant packaging

Regulations vary by country and state, but several authoritative sources shape packaging requirements for cannabis and related products. In the U.S., the Poison Prevention Packaging Act (PPPA) and guidance from the Consumer Product Safety Commission (CPSC) inform child-resistant expectations for potentially hazardous consumer products. Many U.S. states that regulate cannabis sales impose strict child-resistant packaging rules for pre-rolls. In Canada, Health Canada mandates child-resistant packaging for cannabis products. Understanding the applicable regional rules is the first step when specifying a pre roll packaging box.

Design features of an effective child-resistant pre roll packaging box

Mechanical and structural elements to look for

An effective child-resistant pre roll packaging box balances usability for adults with difficulty for children. Common features include:

- Dual-action openings (e.g., press-and-slide or squeeze-and-pull mechanisms)

- Hidden tabs or recessed push points

- Locking inner trays with outer sleeves

- Tamper-evident seals that indicate prior access

- Opaque or non-child-appealing graphics to reduce attraction

Designers must test ease-of-use for the intended adult demographic while ensuring the mechanism resists typical child attempts. In addition to mechanical design, labeling that clearly states 'keep away from children' and dosage/SAFETY information is essential.

Materials and sustainability considerations for pre roll packaging box

Material choices: paperboard, plastic, metal and alternatives

Pre roll packaging box materials influence safety, sustainability, cost, and manufacturing options. Common materials include:

- Paperboard (folding cartons, tubes) — lightweight, cost-effective, printable, and increasingly recyclable when not laminated.

- Rigid boxes with inner locking trays — High Quality feel and robust protection for fragile pre-rolls.

- High-density polyethylene (HDPE) or polypropylene — durable and frequently used for reusable child-resistant containers.

- Metal tins — strong and long-lasting but more costly.

Many brands now seek recyclable, compostable, or FSC-certified paperboard for their pre roll packaging box to meet consumer sustainability expectations. When choosing materials, confirm your chosen approach still enables required child-resistant functionality and any required testing or certification.

Testing and certification for child-resistant pre roll packaging box

How compliance is proven

Child-resistant packaging is typically validated through standardized testing protocols that involve panels of children (to demonstrate resistance) and adults (to demonstrate usability). Depending on jurisdiction, tests may be mandated or audited by regulators. Work with accredited labs to perform these tests; passing certificates or test reports are essential documentation for compliance and can be requested by regulators or retail partners. Retain records for quality control and risk mitigation.

Comparing popular child-resistant pre roll packaging box types

Which design fits your product and brand?

Different pre roll packaging box formats offer trade-offs among cost, look-and-feel, protection, and testing complexity. The table below summarizes common options:

| Packaging Type | Child-Resistant Mechanism | Pros | Cons | Best for |

|---|---|---|---|---|

| Push-and-Turn Tube | Push to unlock, twist to open | Inexpensive, compact, widely accepted | Plastic-focused, lower High Quality feel | High-volume single pre-rolls |

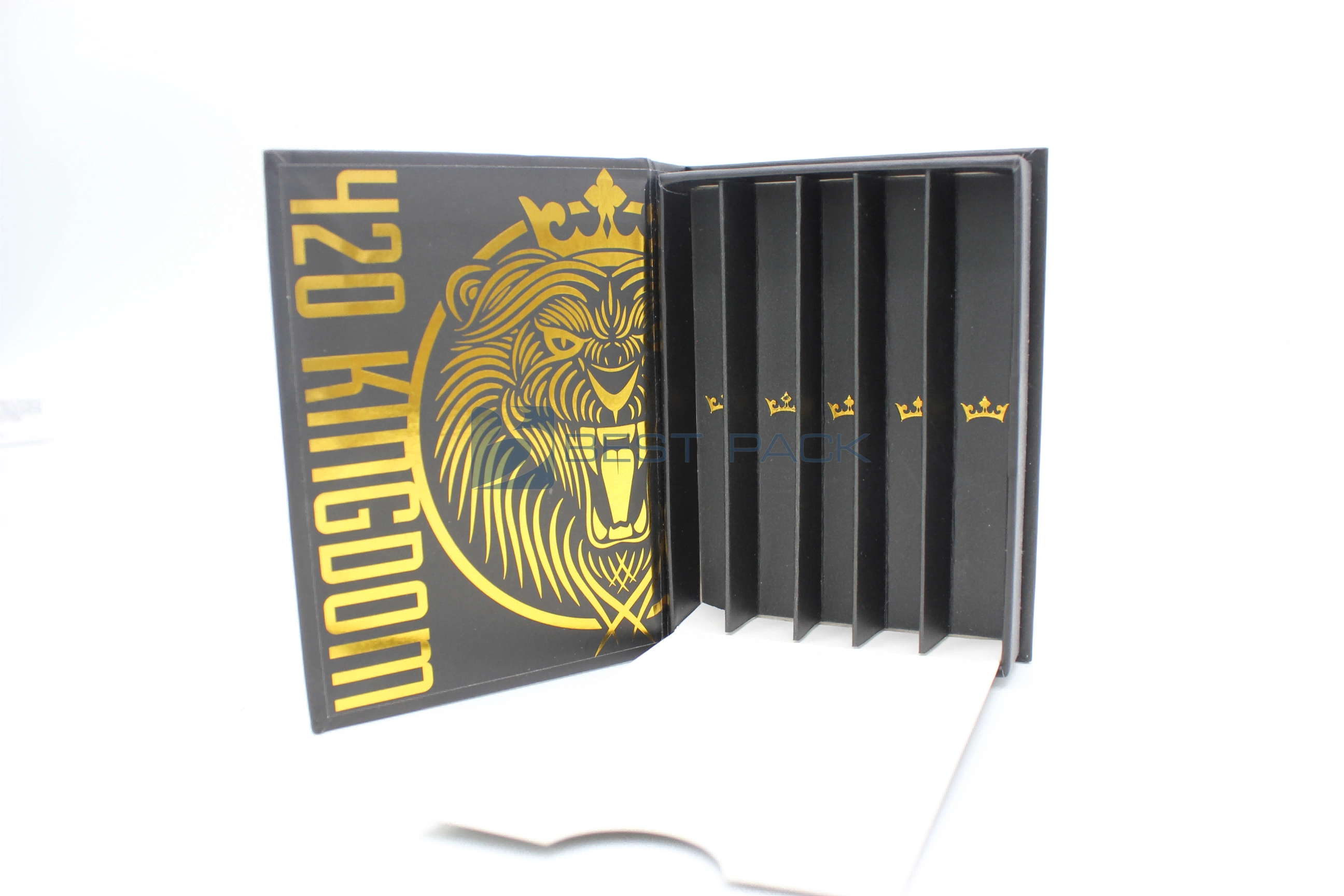

| Slide Tray with Locking Sleeve | Inner tray requires two-step action | High Quality unboxing, protects product | Higher cost, slightly more complex manufacturing | High Quality or multi-pack pre-rolls |

| Hinge-Top with Push Clip | Clip must be pressed while opening | Durable, reusable | Bulkier, higher material cost | Reusable or collector-oriented items |

| Magnetic Child-Resistant Lock | Hidden magnet + two-step release | High-end look, good user experience | Most expensive, magnet sourcing needed | High Quality brands with strong unboxing focus |

Sources for mechanical effectiveness and industry practice include regulator guidance and independent lab reports (see references below).

How to choose the right pre roll packaging box for Best Pack

Decision factors: compliance, cost, brand experience

Selecting the right child-resistant pre roll packaging box requires balancing several factors:

- Regulatory compliance in the jurisdictions where you sell

- Shelf presence and brand identity

- Unit economics and production volumes

- Sustainability goals and material restrictions

- Supply chain reliability and lead times

Start with a regulatory checklist for each market, then shortlist packaging formats that meet the functional requirements. Create prototypes and run adult-use tests, followed by certified child-resistance testing before mass production.

Manufacturing and customization: bringing a pre roll packaging box to market

Working with a packaging partner

Manufacturers of pre roll packaging box solutions should offer end-to-end services from concept and dielines to printing, finishing and child-resistant mechanism assembly. Key capabilities to look for in a partner include in-house graphic printing, structural engineering expertise, quality control for CR features, and support for testing and certification. A reliable partner helps reduce time-to-market and ensures consistent quality as volumes scale.

Best Pack: custom solutions for child-resistant pre roll packaging box

Who we are and what we offer

Best Pack is a custom cannabis cigarette packaging company that provides one-stop services from design and printing to handicraft processing. We constantly insist on offering products of the best quality, excellent services and competitive prices to our customers. At the same time, the company persists in its team-working spirit and develops innovation continually to meet the chance and challenge brought by the Information Technology Age.

Our product range and core competencies

From cannabis protective packaging to cartridge box packaging, our real customer cases showcase our OEM/ODM capabilities, attention to detail, and commitment to quality. Our custom packaging not only enhances Best Pack image but also provides high-quality, tailor-made packaging solutions that elevate brand value, driving more purchasing decisions through promotions and customer feedback.

Best Pack specializes in:

- Child Resistant Packaging Box

- cannabis protective packaging

- vape packaging

- cigarette packaging box

- custom vape cartridge boxes

- cannabis packaging boxes

- custom cannabis packaging

- custom cigarette packaging

We combine structural engineering, high-quality printing, and finishing techniques to deliver packaging that meets safety and branding goals. Our core competitive advantages include:

- Full-service OEM/ODM capability — from concept to production

- Quality control systems and craftsmanship for consistent child-resistant mechanisms

- Competitive pricing through efficient manufacturing and material sourcing

- Design and prototyping support to optimize packaging for testing and certification

- Commitment to innovation and continuous improvement

Our vision and customer value

Our vision is to become the world's leading cannabis and cigarette packaging box manufacturer. Working with Best Pack means your pre roll packaging box will reflect compliance, High Quality presentation, and market-ready durability. Whether you need sustainable paperboard pre-roll tubes with child-resistant closures or High Quality slide boxes with tamper evidence, Best Pack can deliver scalable, customized solutions. Visit our website at https://www.gzbestpack.com/ to view samples and real customer cases.

Cost considerations and lead times for your pre roll packaging box

Budgeting and production planning

Costs depend on material, complexity of the child-resistant mechanism, printing and finishing choices, and order quantity. Simpler plastic or paperboard tubes will cost less per unit, while High Quality trays with magnetic locks or metal components increase cost. Allow additional budget for testing and certification, especially when entering new markets. Typical lead times range from 4–10 weeks for production after approvals, but can vary by order size and current supply chain conditions.

Real-world best practices for packaging safety and marketing

Balancing safety with brand impact

Best practice tips include:

- Prioritize clear safety labeling in addition to mechanical CR features

- Prototype early and iterate — evaluate both adult usability and lab testing results

- Consider sustainable materials that don’t compromise required functionality

- Document test results and supplier quality controls for audits

- Use packaging design to reinforce brand promise while de-emphasizing child appeal

Frequently Asked Questions (FAQ)

Do all states require a child-resistant pre roll packaging box?

Requirements vary. Many U.S. states that regulate cannabis sales require child-resistant packaging; others may impose different rules. Consult local regulators or a compliance attorney for jurisdiction-specific guidance.

Does 'child-resistant' mean 'child-proof'?

No. Child-resistant packaging reduces the likelihood of access by children but cannot guarantee prevention in all cases. Always store products securely and out of reach of children.

How is a pre roll packaging box tested for child-resistance?

Testing typically involves controlled trials with child panels to show resistance and adult panels to show usability. Accredited labs run standardized protocols and issue reports or certificates.

Can child-resistant features be combined with sustainable materials?

Yes. Many CR designs can be implemented with recyclable or FSC-certified paperboard and reduced plastic. Work with your packaging partner to engineer a solution that balances CR performance and sustainability goals.

How long does it take to develop a custom child-resistant pre roll packaging box?

From initial concept to production, expect 8–16 weeks depending on complexity, prototyping cycles, and testing requirements. Rush options may be available but can add cost.

Why choose Best Pack for custom pre roll packaging box solutions?

Best Pack offers end-to-end OEM/ODM services, proven CR manufacturing capabilities, competitive pricing, and a track record in cannabis and cigarette packaging. We support design, prototyping, printing and handicraft processing, helping brands launch compliant and compelling pre-roll packaging.

Contact us / View our products

Ready to design your child-resistant pre roll packaging box?

If you need a compliant, attractive pre roll packaging box, Best Pack can help. Visit our product pages and contact our sales team at https://www.gzbestpack.com/ to request samples, quotes or a consultation. Protect your customers, meet regulatory requirements, and elevate Best Pack with a tailored child-resistant packaging solution.

References

Consumer Product Safety Commission (CPSC) — Poison Prevention Packaging Act

Health Canada — Cannabis Packaging and Labeling Requirements

American Association of Poison Control Centers (AAPCC) — National Poison Data System reports

Industry testing labs and packaging engineering guides on child-resistant packaging

Note: For regulatory specifics and test protocols consult local regulators, accredited testing labs, or legal counsel. The references above represent authoritative institutions that publish guidance on child-resistant packaging and related safety considerations.

Ensuring Child-Resistant Compliance in Custom Cigarette Boxes

Best Printing Techniques for Pre-Roll Packaging Boxes

Tips for buy cigarette case folding paper box

Buyer’s Guide: Custom Printing Options for Cigarette Boxes

About us

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

What services do you provide?

We offer one-stop packaging solutions, including design, printing, and handicraft processing for electronic boxes, plastic boxes, paper boxes, paper bags, and book printing.

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack