Future Trends in Child-Resistant Pre-Roll Packaging

- Future Trends in Child-Resistant Pre-Roll Packaging

- Introduction: Why child-resistant pre roll packaging box matters

- Market Drivers and for Pre-Roll Packaging

- Demand signals shaping packaging choices

- Materials Innovation: Sustainable and Compliant Options

- Material trends for safer, greener pre-roll packaging

- Materials comparison for pre roll packaging box

- Design & User Experience: Balancing Safety with Convenience

- Human-centered CR design for pre-rolls

- Smart Packaging and Traceability

- Connected features that improve safety and brand trust

- Manufacturing Automation and Scalability

- Production trends that reduce cost and improve consistency

- Regulatory Landscape and Safety Standards

- Compliance is non-negotiable for pre roll packaging box

- Sustainability and the Circular Economy

- How sustainability affects packaging decisions

- Branding, Retail Impact and Consumer Preference

- Packaging as a conversion tool at shelf and online

- Cost, ROI and Supply Chain Considerations

- Balancing upfront cost with long-term value

- How Best Pack Supports Future-Ready Pre-Roll Packaging

- OEM/ODM capabilities and real-world case experience

- Practical Recommendations for Brands

- Steps to future-proof your pre-roll packaging box

- FAQ: Common Questions About Child-Resistant Pre-Roll Packaging

- What makes a pre roll packaging box child-resistant?

- Are there international standards for child-resistant packaging?

- How can I make my pre-roll packaging box more sustainable?

- Does child-resistant packaging increase costs significantly?

- How long does it take to develop a custom CR pre-roll packaging solution?

- Can smart features be added without raising environmental impact?

Future Trends in Child-Resistant Pre-Roll Packaging

Introduction: Why child-resistant pre roll packaging box matters

As cannabis markets mature, the intersection of safety, sustainability and brand experience makes the pre roll packaging box a strategic asset, not just a container. Consumers expect packaging to be child-resistant (CR), convenient, attractive and consistent with environmental values. For manufacturers and brands, anticipating future trends in child-resistant pre-roll packaging is essential to reduce compliance risk, improve shelf appeal and lower total cost of ownership.

Market Drivers and for Pre-Roll Packaging

Demand signals shaping packaging choices

Evolving regulation, retailer requirements and consumer preferences drive innovation in the pre roll packaging box segment. Retailers increasingly demand tamper-evident and CR solutions; states and jurisdictions continue to refine cannabis packaging rules; and consumers reward sustainability and convenience. Optimizing packaging for —safety, sustainability, functionality and price—helps brands win visibility and conversions online and in-store.

Materials Innovation: Sustainable and Compliant Options

Material trends for safer, greener pre-roll packaging

Material selection balances recyclability, protection and child-resistance. Key directions include recycled paperboard with inner CR liners, certified compostable bioplastics, lightweight metal tins with tested CR closures, and glass funnels for High Quality SKUs paired with CR outer boxes. Using post-consumer recycled (PCR) content and clear on-pack recycling instructions helps brands meet both regulatory expectations and consumer demand.

Materials comparison for pre roll packaging box

| Material | Recyclability | Typical Cost | Child-Resistance Capability | Customization Options |

|---|---|---|---|---|

| Paperboard | High (if uncoated or recyclable coating) | Low–Medium | Medium (with inner CR mechanism) | Excellent (printable, emboss, window) |

| Bioplastic (PLA, PBAT blends) | Variable (compostable vs not) | Medium–High | Medium (depends on design) | Good (molding complexity) |

| Rigid Plastic (HDPE, PP) | Medium (recyclable in some streams) | Medium | High (engineered closures) | Good (injection mold options) |

| Metal (tin, aluminum) | High (recyclable) | High | High (durable CR lids) | Medium (printing, anodizing) |

| Glass | High | High | High (with CR outer) | Limited (labeling, screen print) |

Design & User Experience: Balancing Safety with Convenience

Human-centered CR design for pre-rolls

Child-resistant packaging must remain usable for adults. Trends emphasize ergonomic opening mechanisms (push-and-slide, dual-action tabs), single-handed operation for accessibility, and clear tamper-evidence. Designers are also reducing packaging complexity—right-sizing boxes to limit wasted space while keeping required CR features—improving shelf efficiency and lowering shipping emissions.

Smart Packaging and Traceability

Connected features that improve safety and brand trust

Smart capabilities—QR codes, NFC tags, and serialized barcodes—enable traceability, age verification, product provenance and digital consumer engagement. Adding scan-based access to lab results, dosing guides, or loyalty offers increases transparency and reduces buyer friction. These features help brands meet both regulatory track-and-trace requirements and consumer demand for trustworthy information.

Manufacturing Automation and Scalability

Production trends that reduce cost and improve consistency

Automation in folding, inserting, tamper-seal application and CR mechanism assembly increases throughput while maintaining quality. Short-run digital printing allows brands to test new designs and SKUs quickly without major tooling costs. Suppliers investing in flexible lines can serve seasonal demand spikes common in cannabis retail.

Regulatory Landscape and Safety Standards

Compliance is non-negotiable for pre roll packaging box

Child-resistant packaging must align with applicable regulations. While cannabis rules vary by jurisdiction, many providers adopt recognized standards such as ISO 8317 (reclosable child-resistant packaging) and emulate requirements used in non-cannabis sectors, like the U.S. Poison Prevention Packaging Act, to demonstrate robust testing. Staying ahead of local labeling, tamper-evidence and CR testing requirements reduces disruption to market entry.

Sustainability and the Circular Economy

How sustainability affects packaging decisions

Brands increasingly prioritize designs that lower carbon footprint and use recyclable or compostable materials. Practically, this means choosing mono-material constructions, minimizing plastic windows, using water-based inks and clear recycling instructions. Closed-loop programs—for example, take-back or refill systems—are emerging for High Quality brands seeking lifecycle differentiation.

Branding, Retail Impact and Consumer Preference

Packaging as a conversion tool at shelf and online

The pre roll packaging box is often the first physical touchpoint with a product. High Quality finishes, structural uniqueness and integrated storytelling (labels linking to lab tests and cultivation methods) increase perceived value. For direct-to-consumer and dispensary sales, clear product information and consistent branding reduce returns and improve customer satisfaction.

Cost, ROI and Supply Chain Considerations

Balancing upfront cost with long-term value

Investing in CR packaging can increase unit cost, but well-engineered designs lower losses from breakage, improve shelf life and reduce compliance fines. Rapid prototyping and modular tooling reduce time-to-market. Working with an experienced OEM/ODM like Best Pack enables bundled pricing for design, printing and assembly that often improves margins compared to piecemeal sourcing.

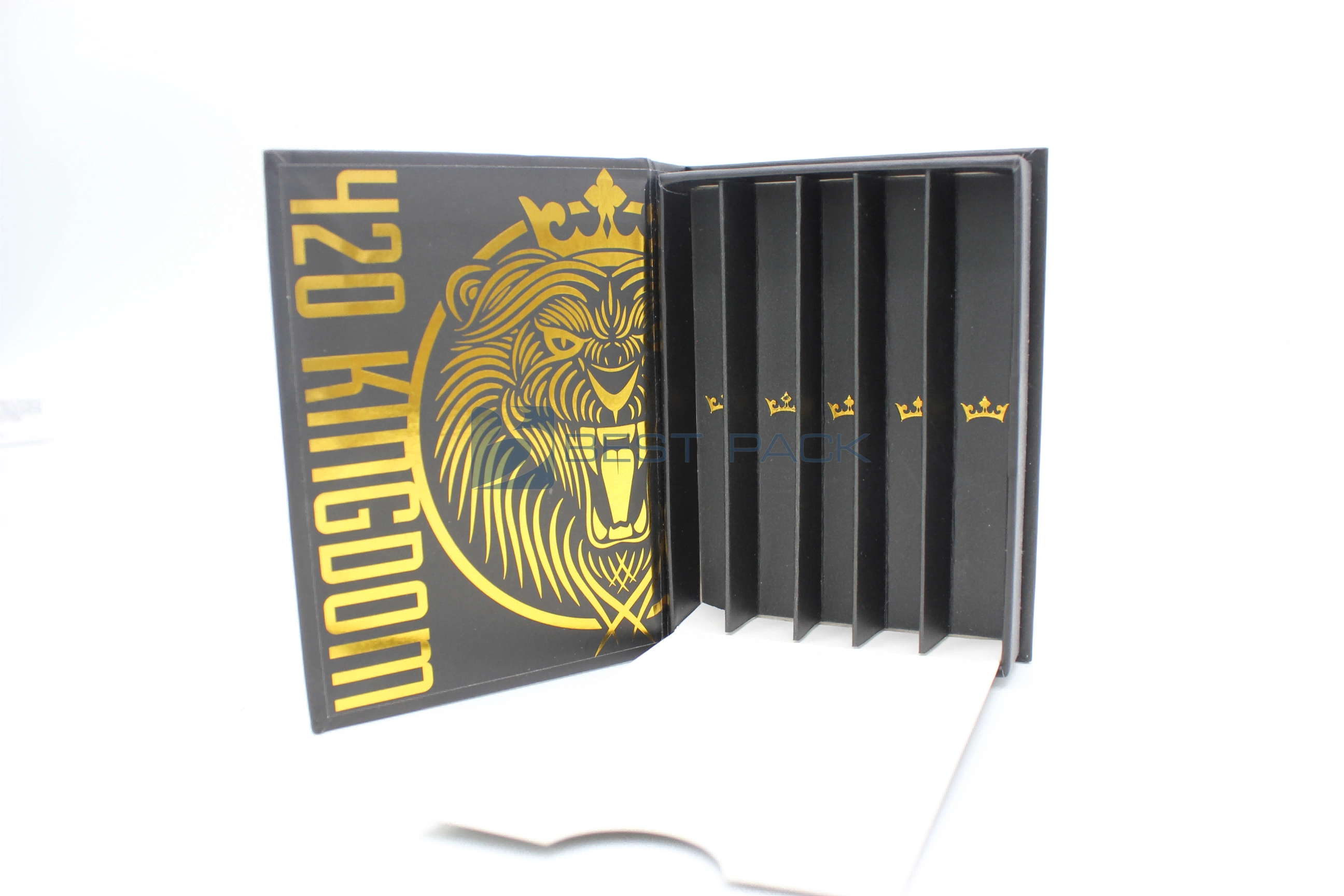

How Best Pack Supports Future-Ready Pre-Roll Packaging

OEM/ODM capabilities and real-world case experience

Best Pack is a custom cannabis cigarette packaging company offering one-stop services from design and printing to handicraft processing. With a portfolio spanning cannabis protective packaging to cartridge box packaging, Best Pack demonstrates OEM/ODM strengths—attention to detail, testing for child-resistance, and flexible print runs. The company focuses on quality, competitive pricing and continuous innovation to meet evolving tech and regulatory challenges. Visit https://www.gzbestpack.com/ for examples and contact options.

Practical Recommendations for Brands

Steps to future-proof your pre-roll packaging box

1) Start with compliance: review local CR and labeling rules. 2) Choose mono-material or easily recyclable assemblies. 3) Integrate a tamper-evident and user-friendly CR closure tested to recognized standards. 4) Add smart features for traceability and consumer education. 5) Work with a partner who offers prototyping, testing and scalable production to iterate quickly.

FAQ: Common Questions About Child-Resistant Pre-Roll Packaging

What makes a pre roll packaging box child-resistant?

Child-resistant packaging uses mechanisms that are difficult for young children to open but remain reasonably accessible to adults—examples include push-and-turn lids, dual-action tabs and inner CR liners. Designs are validated through testing protocols to ensure effectiveness.

Are there international standards for child-resistant packaging?

Yes. One widely-referenced standard is ISO 8317 for reclosable child-resistant packaging. Brands often use established standards and documented testing to demonstrate safety for regulators and retailers.

How can I make my pre-roll packaging box more sustainable?

Use mono-materials, increase PCR content, avoid unnecessary plastics, use water-based inks and minimize secondary packaging. Clear recycling instructions and lightweight designs also improve sustainability metrics.

Does child-resistant packaging increase costs significantly?

There is an added cost for CR mechanisms and testing, but these can be offset by reduced product loss, fewer compliance issues and higher perceived value. Working with an experienced OEM/ODM can optimize cost through integrated services.

How long does it take to develop a custom CR pre-roll packaging solution?

Development time varies: concept to prototype often takes 4–8 weeks depending on complexity; tooling and testing can add additional time. Digital printing short runs can speed validation before larger investments.

Can smart features be added without raising environmental impact?

Yes. Use recyclable NFC tags, minimal inks and digital-first consumer materials (e.g., online lab reports via QR codes) to combine transparency with low material overhead.

For further assistance designing compliant, sustainable and on-brand pre roll packaging box solutions, Best Pack offers OEM/ODM services that integrate design, printing and assembly tailored to cannabis packaging requirements.

Tips for Artwork and Logo Placement on Cigar Boxes

How to Choose the cigar box manufacturers manufacturer and supplier ?

Tips for buy child resistant paper box

Top Materials for Child-Resistant Pre-Roll Packaging Boxes

About us

Are you able to do design for my products?

Yes, just send us your logo artwork in Vector file, such as AI or PDF format,and text information you want to print ,we can put it on box to make the design to let you check. Once you say ok, then we go on to make samples or production.

When can I get the quotation?

1. The quotation will be offered within 24 hours after getting your detailed request.

2. If you get the urgent inquiry, please call us or mark it via E-mail, then we could make it into priority list.

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

FAQs

Can you ship internationally?

Yes, we export worldwide and work with reliable logistics partners for timely delivery.

Custom Pre Cone 5 Pack Magnetic Paper Cigarettes Box Pre Roll Packaging Box

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Best pack

Best pack

Best pack