Packaging Paper Tube Procurement: Benefits for Childproof Products

- Packaging Paper Tube Procurement: Benefits for Childproof Products

- Why choose a packaging paper tube for childproof products?

- Product highlight: Custom Recyclable Cardboard Childproof Child Resistant Packaging

- How a packaging paper tube meets childproofing needs

- Standards and compliance for child-resistant packaging paper tube

- Materials and construction: what to look for in a packaging paper tube

- Sustainability benefits of choosing a recyclable packaging paper tube

- Comparison: packaging paper tube vs common alternatives

- Procurement considerations for packaging paper tube

- Customization and branding opportunities on packaging paper tube

- Cost analysis and ROI for switching to recyclable paper tubes

- Practical industries and product types for packaging paper tube

- Procurement best practices checklist for packaging paper tube

- Case example: expected outcomes after switching to a recyclable childproof paper tube

- Brand advantages — why choose Best Pack for packaging paper tube procurement?

- Frequently Asked Questions (FAQ)

- Q: Are paper tubes with lock buttons truly child-resistant?

- Q: Is the Custom Recyclable Cardboard Childproof Round Paper Tube recyclable in curbside programs?

- Q: How does a paper tube compare to plastic for moisture-sensitive products?

- Q: What lead time should procurement expect for custom childproof paper tubes?

- Q: Can the lock button mechanism be integrated into high-speed packaging lines?

- Contact and product call-to-action

- References and authoritative sources

- Final note

Packaging Paper Tube Procurement: Benefits for Childproof Products

Why choose a packaging paper tube for childproof products?

When you select packaging for items that must be kept away from children—medicines, supplements, e-cigarette cartridges, small batteries, or household chemicals—the packaging must balance safety, usability and compliance. The packaging paper tube is an increasingly popular format that delivers tamper resistance, structural protection and an opportunity to meet sustainability goals while still incorporating childproof features. In our guide on packaging paper tube procurement, we explore how these packaging solutions provide added benefits for childproof products, offering a safer and more reliable option for parents. After learning the benefits, it’s important to understand how to source custom recyclable child-resistant packaging paper tubes, ensuring both safety and environmental sustainability.

Product highlight: Custom Recyclable Cardboard Childproof Child Resistant Packaging

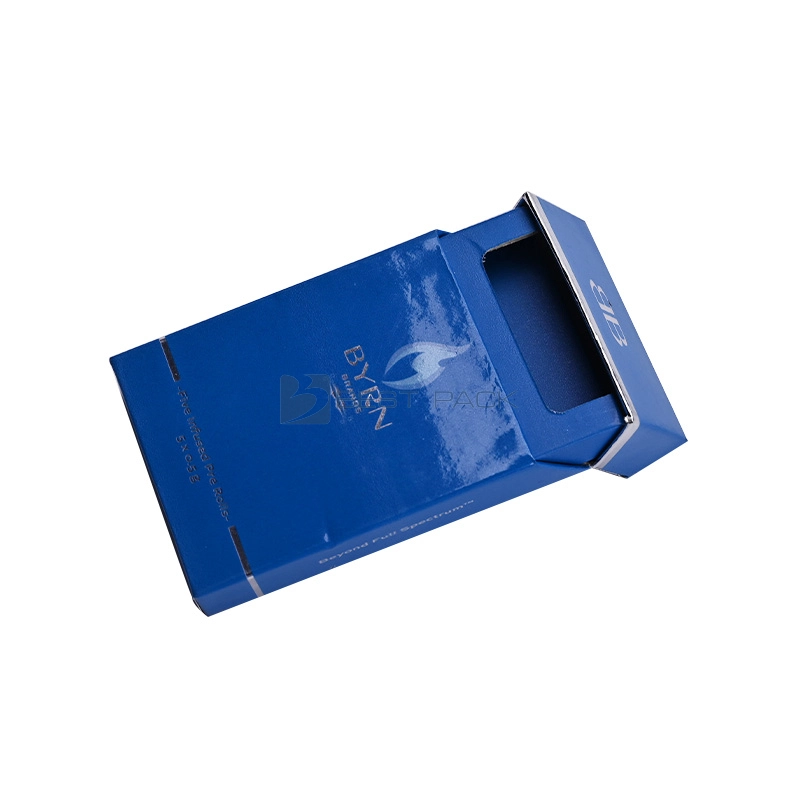

Product name: Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button

Product intro:

Best Pack’s Custom Recyclable Cardboard Childproof Packaging Box offers secure, eco-friendly storage with a child-resistant lock button. Designed as a round paper tube box, it ensures safety and sustainability, ideal for protecting products while supporting green packaging solutions.

How a packaging paper tube meets childproofing needs

Packaging paper tubes can be engineered for reclosable child-resistant action by combining mechanical design (locking buttons, push-and-turn caps, interlocking tabs) with structural stiffness from multi-layered cardboard. For consumers, these tubes are intuitive—open and close motions mimic traditional containers—while providing a tested barrier against curious children. Including a lock button or similar mechanism allows the tube to fulfill practical child-resistant function without introducing excessive complexity for adult users.

Standards and compliance for child-resistant packaging paper tube

Any child-resistant packaging should reference recognized standards and regulations. Key frameworks include the US Poison Prevention Packaging Act (PPPA) enforced by the CPSC and international norms such as ISO 8317 for reclosable child-resistant packaging. Procurement of a packaging paper tube for childproof products should verify testing reports and conformity to applicable local regulations to reduce legal and safety risk.

Materials and construction: what to look for in a packaging paper tube

Not all paper tubes are the same. For childproof products, focus on:

- Multi-ply recycled cardboard for rigidity and crush resistance.

- Inner liner or insert options to protect moisture-sensitive goods.

- Child-resistant mechanical features such as lock buttons, push-and-turn mechanisms, or interlocking caps that meet testing protocols.

- Food-safe or pharmaceutical-grade coatings when packaging consumables.

Sustainability benefits of choosing a recyclable packaging paper tube

Switching to recyclable paper tubes reduces reliance on single-use plastics and leverages existing municipal recycling streams. Paperboard and cardboard have high recycling rates compared with many plastic formats, and a circular design approach can lower lifecycle greenhouse gas emissions. For brands that must communicate environmental credentials, using a Custom Recyclable Cardboard Childproof packaging tube supports both safety and sustainability claims.

Comparison: packaging paper tube vs common alternatives

Below is a comparison table summarizing the primary differences between packaging paper tubes and common alternatives for childproof products.

| Feature | Packaging Paper Tube (cardboard, lock button) | Rigid Plastic Tubes/Boxes | Blister Packs / Foil Seals |

|---|---|---|---|

| Child-resistant capability | High if designed with tested lock mechanisms | High (proven closures), often heavier | Medium — depends on secondary closures |

| Sustainability | High — recyclable and often made from recycled fiber | Low to medium — depends on recyclable resin and local recycling | Low — multilayer laminates difficult to recycle |

| Cost (per unit) | Medium — competitive at scale | Medium to high | Low to medium |

| Branding & customization | Excellent — printability, embossing, coatings | Good — labels or direct printing | Limited — primarily printed cards or sleeves |

| Protection (crush/moisture) | Good (with correct ply and insert) | Excellent | Good for single-use items |

Procurement considerations for packaging paper tube

Procurement teams should treat childproof packaging as a regulated purchase, not a commodity buy. Key considerations:

- Compliance: Request test certificates for child-resistant performance and conformity to relevant standards (e.g., ISO 8317, PPPA guidance).

- Material sourcing: Verify recycled content percentage and certifications (FSC, PEFC where applicable).

- MOQ and lead times: Custom features (lock buttons, inserts, print runs) can affect minimum order quantities and production timelines.

- Supply chain risk: Dual sourcing and inventory buffers reduce risk for critical product launches.

- Cost versus total value: Consider end-of-life savings, brand value and potential regulatory risk mitigation when comparing unit prices.

Customization and branding opportunities on packaging paper tube

Paper tubes are excellent for High Quality visual presentation. Options include full-colour print, embossing, matte or gloss coatings, spot UV, window cut-outs, and internal liners. The Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button can be tailored to carry brand storytelling while still housing secure child-resistant mechanics. Custom dielines and inserts also enable product staging and tamper evidence.

Cost analysis and ROI for switching to recyclable paper tubes

While unit cost can be comparable or slightly higher than basic plastic, the ROI emerges through improved brand perception, potential reductions in regulatory risk, and alignment with sustainability targets that may affect procurement decisions from major retailers. Savings may also occur through optimized shipping (lighter weights than rigid plastics in some configurations) and recyclable waste management credits in some regions.

Practical industries and product types for packaging paper tube

Packaging paper tubes with childproof features are suitable for:

- Pharmaceuticals and OTC medicines

- Vitamins and supplements

- CBD and cannabis-derived products where legal

- Small consumer electronics and batteries

- Household chemicals and garden products

Procurement best practices checklist for packaging paper tube

Use this checklist when evaluating vendors and samples:

- Obtain child-resistant testing reports and confirmation of the test standard used.

- Request material certificates (recycled content, FSC/PEFC if required).

- Order functional prototypes for usability and durability tests.

- Confirm print quality samples and color matching for brand consistency.

- Validate packing, palletization and shipping samples for logistics planning.

- Negotiate trial orders with defined KPI reviews before full-scale roll-out.

Case example: expected outcomes after switching to a recyclable childproof paper tube

A mid-size supplement brand that switched a sealed plastic tube to the Custom Recyclable Cardboard Childproof Round Paper Tube Box with Lock Button reported:

- Reduced plastic packaging by 75% by weight.

- Improved shelf appeal and perceived product value.

- Successful retailer acceptance tied to sustainability commitments.

Brand advantages — why choose Best Pack for packaging paper tube procurement?

Best Pack combines specialized expertise in child-resistant mechanisms with eco-conscious material selection. Advantages include:

- Proven childproof lock-button mechanisms designed for usability and conformity testing.

- Customizable printing and structural options to match brand identity.

- Recyclable, high-recycled-content cardboard choices and supplier transparency for sustainability reporting.

- Prototype and testing support so procurement and QA teams can validate performance prior to volume buys.

Frequently Asked Questions (FAQ)

Q: Are paper tubes with lock buttons truly child-resistant?

A: When designed to recognized standards and validated by testing (e.g., ISO 8317 or applicable national protocols), lock-button paper tubes can provide an effective child-resistant barrier. Always request certified test reports from your supplier.

Q: Is the Custom Recyclable Cardboard Childproof Round Paper Tube recyclable in curbside programs?

A: In most regions, plain cardboard tubes are recyclable in curbside paper recycling. The recyclability of tubes with coatings, inserts or mixed-material components depends on local recycling capabilities. Suppliers should disclose material makeup to ensure proper end-of-life handling.

Q: How does a paper tube compare to plastic for moisture-sensitive products?

A: Paper tubes can be engineered with inner liners or barrier inserts (e.g., wax coatings, PE liners, or separate sealed inner containers) to protect moisture-sensitive contents. The right inner solution depends on product sensitivity and regulatory constraints.

Q: What lead time should procurement expect for custom childproof paper tubes?

A: Lead times vary by complexity. Simple printed runs may take 4–8 weeks; custom lock mechanisms, tooling and certification can extend timelines. Discuss MOQs and lead times early in the procurement process.

Q: Can the lock button mechanism be integrated into high-speed packaging lines?

A: Yes — modern paper tube designs can be tailored for automated filling and closing. Suppliers should provide design-for-manufacturing guidance to ensure compatibility with your plant's equipment or co-packers.

Contact and product call-to-action

To evaluate how the Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button fits your product and regulatory needs, request a prototype or speak with a packaging specialist. Contact Best Pack to get a sample, compliance documents and a quotation tailored to your SKU and volume.

References and authoritative sources

- U.S. Consumer Product Safety Commission — Poison Prevention Packaging Act: https://www.cpsc.gov/Regulations-Laws--Standards/Statutes/Poison-Prevention-Packaging-Act

- ISO 8317 — Child-resistant packaging for reclosable packages: https://www.iso.org/standard/35712.

- U.S. Environmental Protection Agency — Paper and Paperboard Material-Specific Data: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/paper-and-paperboard-material-specific-data

- Wikipedia — Paperboard: https://en.wikipedia.org/wiki/Paperboard

- Ellen MacArthur Foundation — Circular Economy and Packaging: https://www.ellenmacarthurfoundation.org

Final note

Packaging paper tube procurement for childproof products provides a pragmatic path to combine safety, branding and sustainability. By selecting a tested, recyclable solution such as the Custom Recyclable Cardboard Childproof Child Resistant Packaging Child Proof Round Paper Tube Box with Lock Button and following procurement best practices, brands can reduce risk, satisfy retailer and regulatory requirements, and deliver a positive consumer experience.

Ensuring Child-Resistant Features in Cigarette Boxes

Top Logo Printing Techniques for Cigarette Packaging

Lead Times & Supply Chain Tips for Cigarette Box Procurement

Packaging Regulations Every Brand Should Know About Child-Proof Paper Boxes

About us

Leading time for samples production?

Normally we need 3-7 days for samples making, 10-12 days to complete your orders,but the delivery time more depends on the order QTY.

The process of your packaging box production?

1. Make knife mold as per box size and structure

2. order material as per mold

3. make printing on material if need to print

4. suppress and cut material

5. Makeboxes with glue edge in machine

6. Package boxes into cartons

How many kinds the printing process you have?

We can make Silk screen printing, offset printing, and also hot silver stamping

How much of your samples cost ?

1. If samples are without printing, we can make free samples as per your box size or structure;

2. If samples are silk printing, normally USD 25 per color,depending on your logo colors;

3. If samples are offset printing, need USD 180 as offset printing mold cost is high.

FAQs

Do you support custom designs?

Yes, we provide custom packaging designs tailored to your brand and product needs.

Custom Printed Paperboard Cardboard Cigarette Box Packaging Case Disposable Paper Box for Cigarette Clamshell paper box

Custom Vape Packaging Box with CR Telescoping Design

The CR telescoping box is a sophisticated and secure packaging solution designed specifically for vape products. Featuring a telescoping (two-piece) structure, this box offers excellent protection and an elegant presentation, enhancing both the unboxing experience and brand appeal.

Custom Logo Child-Resistant Pre-Roll Box Packaging Biodegradable Handmade Luxury 5 Pack Embossing Childproof Pre Roll Package

Custom CR Vape Packaging Cardboard Boxes with Child-Resistant Design

CR custom vape packaging cardboard boxes are specially designed child-resistant packaging solutions crafted to ensure safety, protection, and premium presentation for vape products. Made from sturdy cardboard materials, these boxes balance regulatory compliance with brand aesthetics.

Best pack

Best pack

Best pack